Contact Us

Tel: +86 0554-4880666

E-mail: cad003@anhzt.com

Add: No.55 Yongle Road, Xinqiao International Industrial Park, Shouxian County, Huainan City, Anhui Province

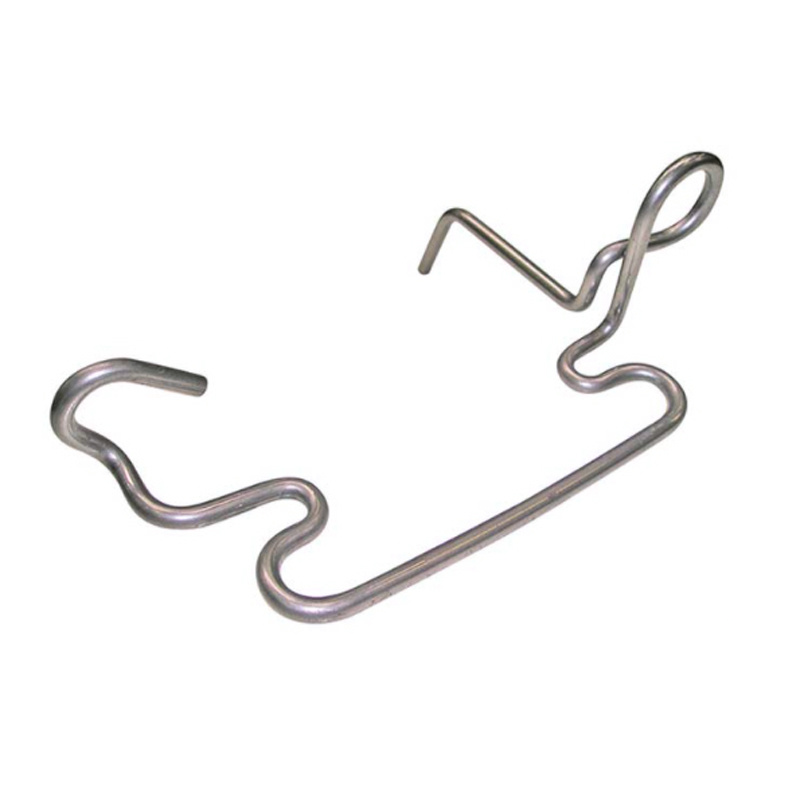

Soft connection

Categorie:

Flexible connection

definition: Flexible connection is made of multiple layers of copper foils superimposed and welded by polymer diffusion welding, with a smooth surface and no welding scars

. Function: With its good flexible conductive function, the flexible connection can eliminate the problem of poor conductivity of the battery pack caused by loose fasteners due to vibration during the operation of the car; at the same time, the insulating layer can slow down the oxidation corrosion of the internal copper foil and meet the insulation requirements between electrical components.

Classification: Copper flexible connection; Aluminum flexible connection;

Applicable scenarios: Power equipment, high-voltage electrical appliances, vacuum electrical appliances, mining explosion-proof switches, automobiles, locomotives

Features: Overall processing without welds; Highly protective housing; Spray-coated wear-resistant surface; Strong anti-interference ability; Metal waterproof joint; Measurement of harsh media; Easy installation and debugging; No leakage risks; Durable

Copper soft connection operating temperature: -40℃-300℃

New energy electric vehicle soft connection: battery connection copper busbar; pack package series copper busbar; blade battery connection copper busbar; heat shrink tube soft connection

Soft connection:

Material: T2 copper foil, copper content ≥99.95%

Copper surface treatment: bare copper, tin plating, nickel plating, silver plating

Insulation layer: heat shrink tubing, plastic spraying, plastic dipping

Customization: New energy soft connections are mostly customized, and holes can be drilled on the contact surface according to

the drawings Size: Developed and produced according to the drawings

Provide customers with professional new energy soft connection solutions

Welding methods of copper foil soft connection:

1. Press welding soft connection: Press welding is to press the copper foil laminated parts together, use molecular diffusion welding, and press welding through high current heating; copper foil: 0.05mm-0.3mm thick

2. Brazing soft connection: Brazing is to press the copper foil laminated parts together, use silver-based brazing material, and weld with flat copper blocks; copper foil: 0.05mm-3mm thick

Keywords:

Soft connection

Prev:

:Next

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Recommend

online message